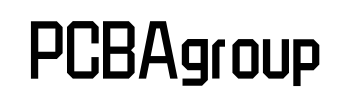

PCBAgroup - A Leading PCBA Manufacturer in China

Years of experience in serving major clients,with long-term partnerships with listed companies such as Midea and Little Bear

Reliable raw materials you can trust.

We source only verified, high-quality components and PCB materials, backed by strict incoming inspection and testing to protect your build quality from the start.

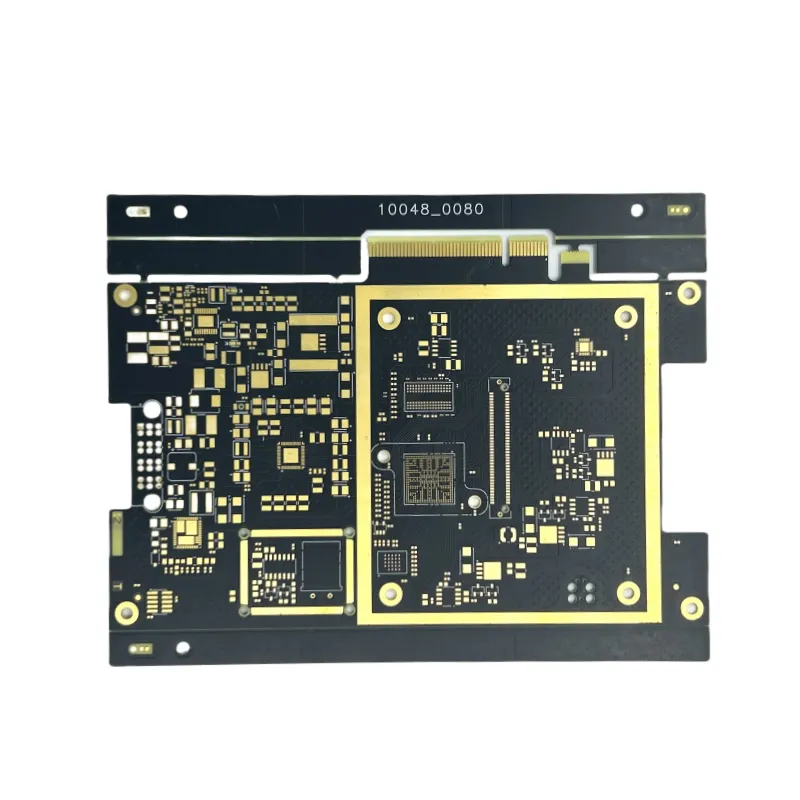

Consistent product quality

Shipment after full inspection. Every PCB/PCBA is checked before delivery with quality controls that meet or exceed common industry standards—helping you reduce defects, rework, and field failures.

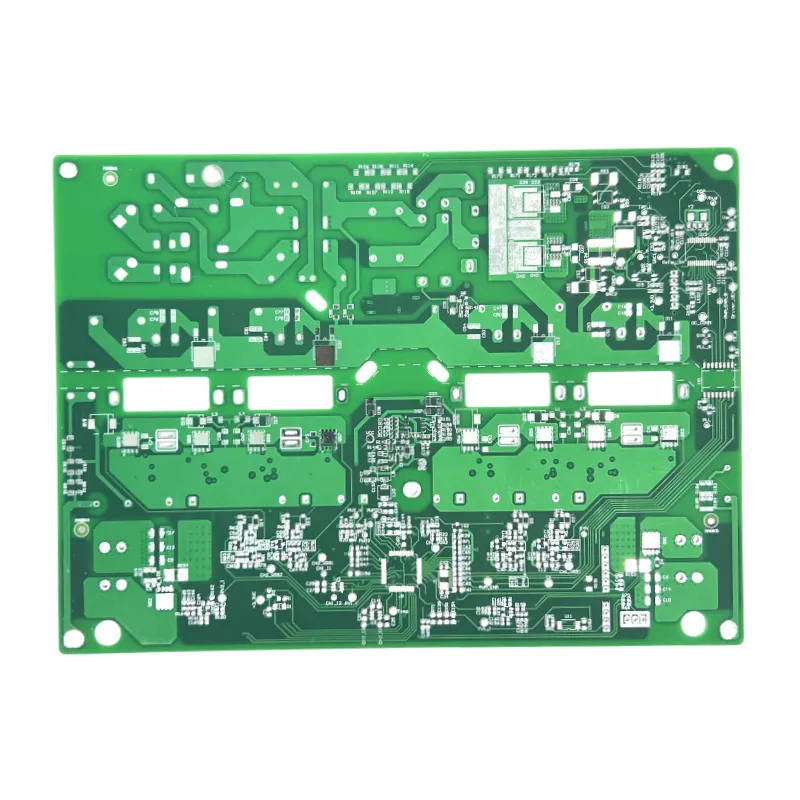

Fast, flexible delivery for urgent projects

With agile production scheduling and streamlined workflows, we support quick-turn PCB and PCBA orders, with selected builds completed within 3 days.

About PCBAgroup Factory in China

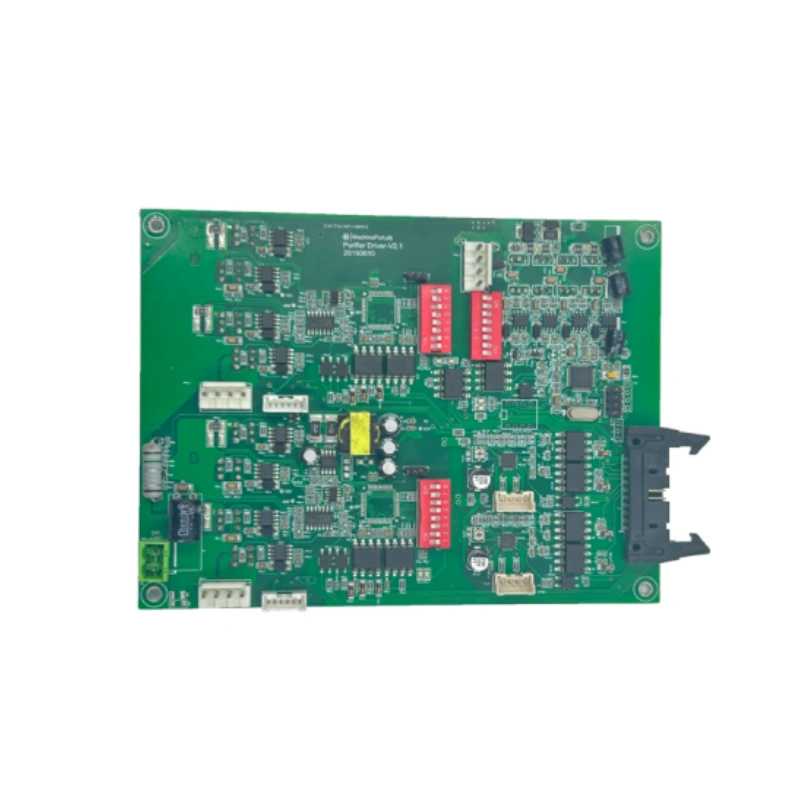

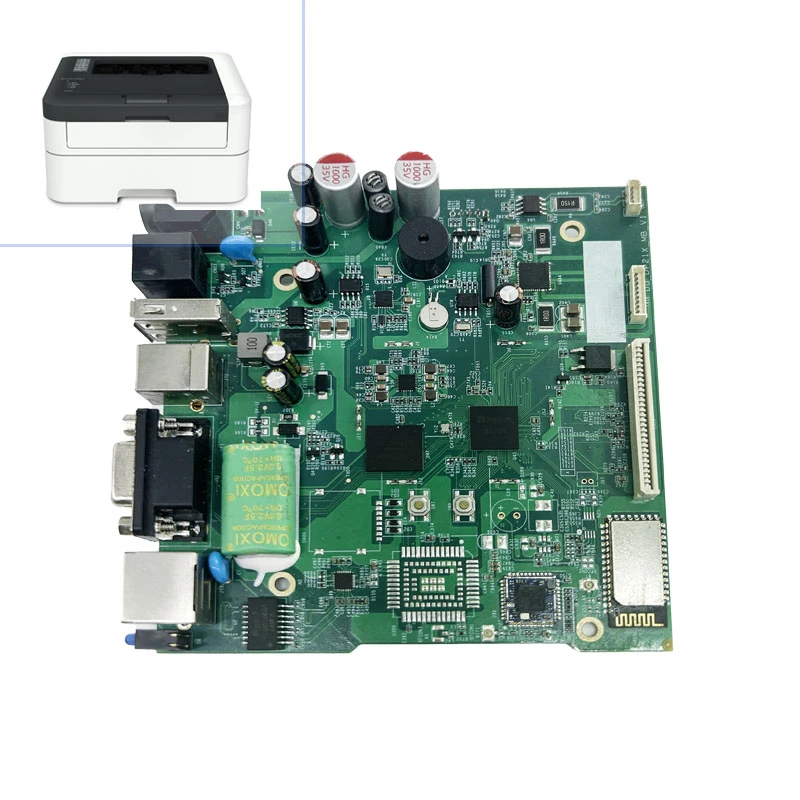

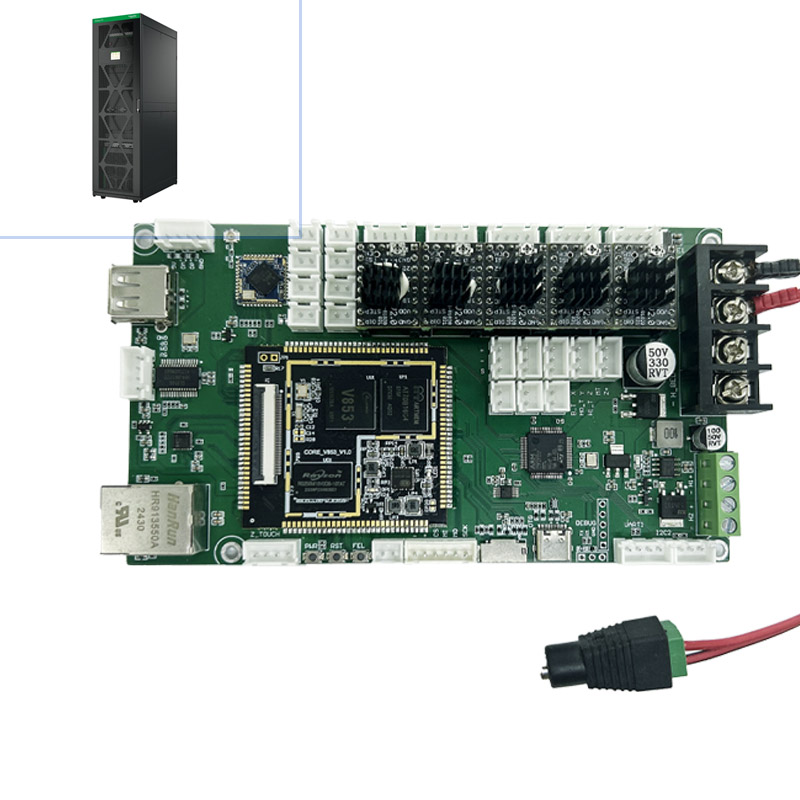

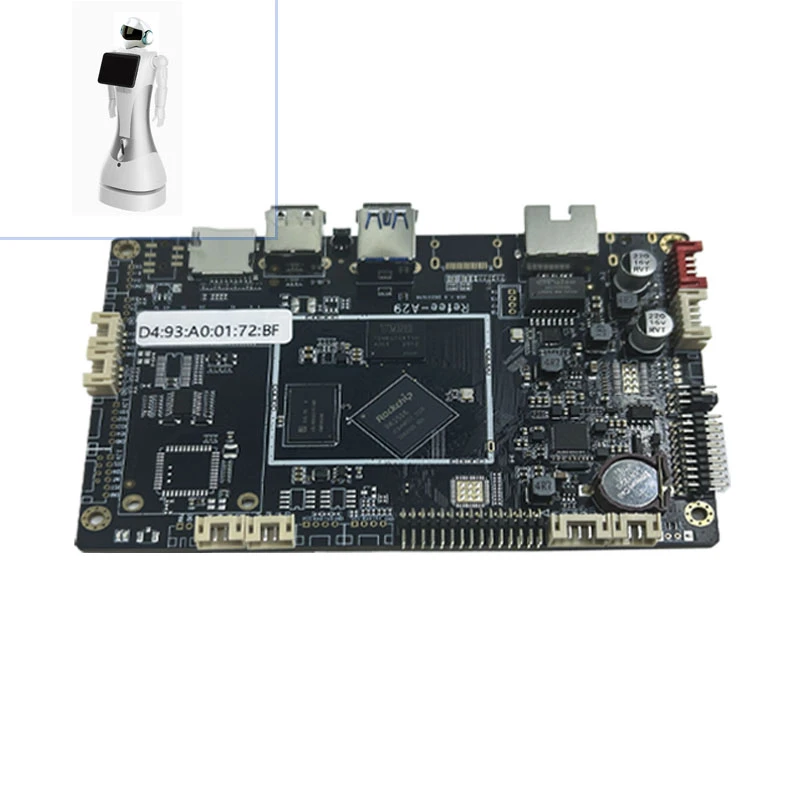

16+ years of PCB & PCBA manufacturing experience in China. From prototypes to mass production, we provide one-stop PCB fabrication and PCBA assembly services

PCBAgroup – Your Trusted Partner for High-Quality PCB Assembly Solutions.

Experience Reliable, Rapid, and Professional Services that Boost Your Production Efficiency. Elevate Your Projects with China’s Leading Manufacturer.

what we can do

Experience Reliable, Rapid, and Professional Services that Boost Your Production Efficiency. Elevate Your Projects with China’s Leading Manufacturer.

Our Advantage

Experience Reliable, Rapid, and Professional Services that Boost Your Production Efficiency. Elevate Your Projects with China’s Leading Manufacturer.

Timely Delivery

Being a original factory,have two branches with 8 high-speed SMT production lines to ensure production capacity and delivery time.

High Quality

Relying on highly integrated supply chain,we strictly follow the ISO9001 and TS16949 systems to ensure products' quality.

Fully Traceability

Fully implement of EMS/ERP digital management system to achieve live data and quality traceability clearly and efficiently.

After-asles Services

Providing timely after-sales response,and serve you online through the whole process.

Qualified Customization

15 R & D engineers to support for customized OEM / ODM PCB PCBA projects.

Good Communication

A professional bilingual foreign trade team can effectively communicate with our overseas customers.

PCB Assembly Machine

PCB Assembly Process

IQC

PCB Drying Oven

Solder Paste Machine

SPI

Hi-Speed SMT Machine

Re-Flow Soldering

FAI

QC

DIP

PCBA Depanelizer

Testing

Packaging

Quality Contral Process

To ensure stable quality and high reliability for every PCBA order, we follow a strict 8-step quality control process from pre-production review to final inspection.

01-Process review

Assess and inspect the particularity of the PCBA manufacturing process in advance, guide the production, and improve the quality from the process technology.

02-IQC Incoming Quality Control

1.Check whether the resistance and capacitance values are correct 2.Check whether the pads on the components and the board are consistent 3.Confirm whether the incoming quantity is accurate 4.Check whether the components are abnormal

03-SPI Solder Paste Inspection

SPI can detect whether the solder paste is sufficient and uniform, which can effectively prevent production quality problems in advance caused by poor solder paste printing.

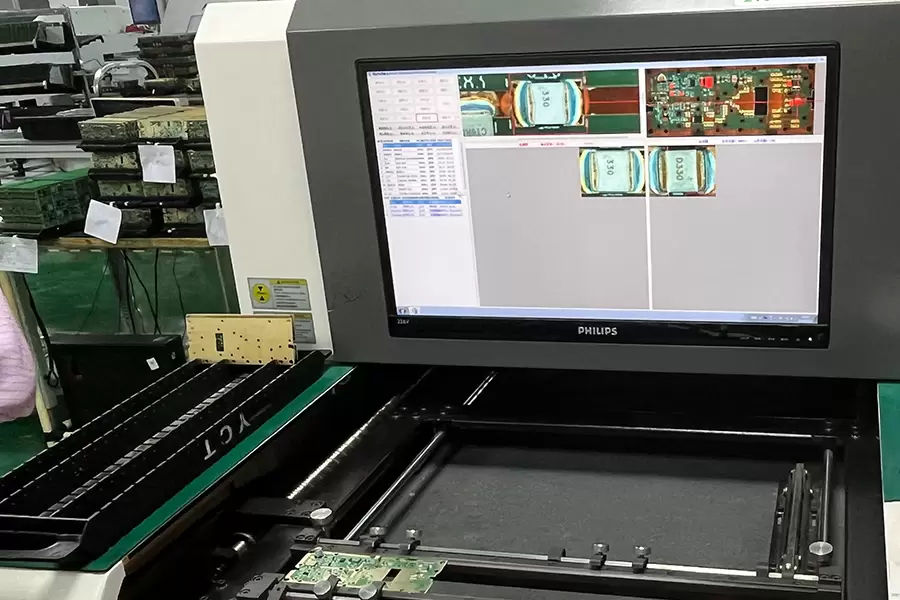

04-Online AOI Inspection

The AOI can detect the wrong solder, reverse solder, false solder, empty solder, incomplete solder, short circuit, offset, tombstone, etc. after reflow soldering. And it can also detect excessive solder, less solder, continuous solder and other undesirable phenomena in the appearance of PCBA solder joints.

05-First sample test

Combined with Gerber, BOM and coordinate files, the resistance and capacitance in the completed PCBA are verified again by the first-sample tester to ensure the correctness of all parameter values.

06-Off-line AOI inspection

According to the IPC610D standard, inspect the soldered surface mount PCBA for errors, omissions, and false connections.

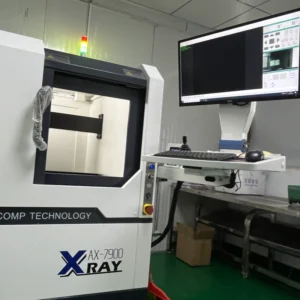

07-X-Ray welding inspection

Inspect the solder joints of invisible components to ensure the reliability of each solder ball of the BGA.

08-QC manual inspection

Refers to the standard IPC--610 inspection standard, and the finished board is visually inspected to ensure 100 % Good products shipped.

How to Place an Order and Request a Quote

1.Send Your Quote

Upload your design files and requirements to receive a transparent and accurate quotation.

2. Request Sample

Want to verify quality first? Request a sample to see our craftsmanship and material standards up close.

3. Place Your Order

Confirm the quote and lead time online. Sign the order to officially queue your project for production.

4. Start Production

Our expert team utilizes advanced equipment to begin manufacturing, strictly adhering to your specifications.

5. Quality Inspection

Every batch undergoes multiple automated and manual inspections to ensure zero-defect delivery.

6. Shipping

Once products pass final inspection, we arrange secure shipment using optimal logistics per your request.