PCB Assembly Service

Want to learn more about PCBA? Please click What is PCBA?

Our PCBA Manufacturing Products

A high-quality PCBA manufacturer, specializing in fast SMT assembly and DIP insertion for small and medium batches, trusted by clients in industries including industrial control, smart home, medical, automotive, and IoT.

Products Show Cases

PCBAgroup offers high-quality PCBA solutions across various industries, including medical, aerospace, military, industrial, telecom, LED, electronics, and more.

PCB Assembly Capabilities

| Item | Item Name | PCBA Capability | |

|---|---|---|---|

| 1. | Lead Time | Our assembly timeframes vary, ranging from 24 hours to several weeks, allowing you to choose the option that best fits your schedule and budget. Due to the complexities involved in determining turnaround times for PCBA services, our policy states that the assembly timeframe begins only after all parts are ready and the necessary documentation is complete. This includes PCB files (such as Gerber files and other related formats), centroid files (Pick & Place or XY data), bill of materials (BOM), and any additional documents or images required for our assembly process. | |

| 2. | Parts Source | Consigned/kitted | We prefer that you supply all components for our PCBA services. If you choose this option, please ensure to send us all the necessary components along with a bill of materials (BOM) file. Additionally, provide a detailed packing list that includes the item number, customer or manufacturer’s part number, and the quantity for each kit. This will help us streamline the assembly process and ensure accuracy in your order. |

| Turn-key | Leveraging our extensive and robust network for parts sourcing, we proudly offer turn-key PCBA services without any markup on parts costs. We understand the significant price disparities among suppliers; therefore, we prioritize sourcing from reliable vendors, even if they do not provide the lowest prices. Rest assured, we will always seek your approval before making any purchasing decisions to ensure transparency and alignment with your expectations. | ||

| Partial Turn-key/Combo | In our standard practice, we invite you to provide the primary devices and components, while we take care of sourcing the remaining parts for you. Similar to our turn-key service, we emphasize transparency and collaboration by seeking your approval on every detail concerning parts, including price, quality, and availability. This approach ensures that you remain informed and confident in all sourcing decisions. | ||

| 3. | Assembly Options | We offer Surface Mount (SMT), Thru-Hole (THT) and hybrid of both. We also offer single or double-sided placement. | |

| 4. | Types of Solder | We offer both leaded and lead-free (RoHS Compliant) assembly services for our customers. Please choose one to best fit your PCB and the parts on the PCB. | |

| 5. | Stencils | We use laser cut stainless steel stencils to ensure high reliability for fine pitch and BGA components. Nano coating is available upon request. | |

| 6. | Minimum Order | Our minimum is as low as 5 pieces. We do not want you to pay for what you do not need indeed to save you money. | |

| 7. | Component Size |

| |

| 8. | Component Package | We accept parts in Reels, Cut Tape, Tube & Tray, Loose Parts and Bulk. | |

| 9. | Board Dimension |

| |

| 10. | Board Shape | We can assemble boards in Rectangular, Circular and any Odd Shapes. (For shapes other than rectangle, you need to panelize the boards in an array, and add break-away rails at the two longer paralleled edges of the panelized boards to ensure that the boards can be assembled by the machine.) | |

| 11. | Board Type | Currently we handles Rigid boards mostly. As we have the ability to handle flex and rigid-flex boards, please contact us if your boards are of flex or rigid-flex. | |

| 12. | Repair & Rework | Repair and rework can be difficult, but we do. Our BGA reballing service with which we can safely remove the misplaced BGA, reball it and put it back on the PCB correctly. It is cost-effective. | |

PCB Assembly Process

IQC

PCB Drying Oven

Solder Paste Machine

SPI

Hi-Speed SMT Machine

Re-Flow Soldering

FAI

QC

DIP

PCBA Depanelizer

Testing

Packaging

Quality Contral Process

To ensure stable quality and high reliability for every PCBA order, we follow a strict 8-step quality control process from pre-production review to final inspection.

01-Process review

Assess and inspect the particularity of the PCBA manufacturing process in advance, guide the production, and improve the quality from the process technology.

02-IQC Incoming Quality Control

1.Check whether the resistance and capacitance values are correct 2.Check whether the pads on the components and the board are consistent 3.Confirm whether the incoming quantity is accurate 4.Check whether the components are abnormal

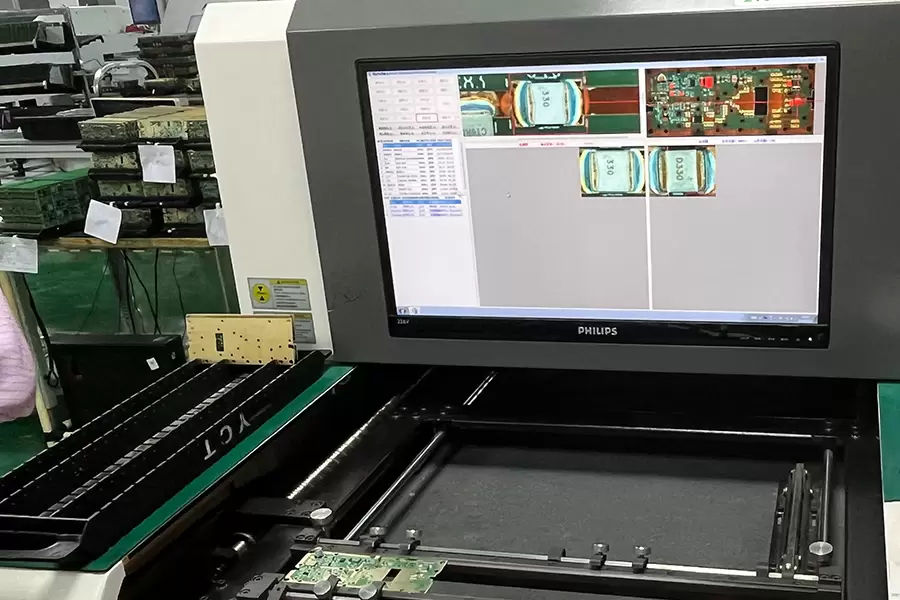

03-SPI Solder Paste Inspection

SPI can detect whether the solder paste is sufficient and uniform, which can effectively prevent production quality problems in advance caused by poor solder paste printing.

04-Online AOI Inspection

The AOI can detect the wrong solder, reverse solder, false solder, empty solder, incomplete solder, short circuit, offset, tombstone, etc. after reflow soldering. And it can also detect excessive solder, less solder, continuous solder and other undesirable phenomena in the appearance of PCBA solder joints.

05-First sample test

Combined with Gerber, BOM and coordinate files, the resistance and capacitance in the completed PCBA are verified again by the first-sample tester to ensure the correctness of all parameter values.

06-Off-line AOI inspection

According to the IPC610D standard, inspect the soldered surface mount PCBA for errors, omissions, and false connections.

07-X-Ray welding inspection

Inspect the solder joints of invisible components to ensure the reliability of each solder ball of the BGA.

08-QC manual inspection

Refers to the standard IPC--610 inspection standard, and the finished board is visually inspected to ensure 100 % Good products shipped.

Why Choose PCBAgroup

One-Stop Service:

16 years of turnkey PCBA manufacturing experience.

Quality Focus:

Strictly comply with ISO9001, ISO13485 standards.

High-Speed Delivery:

Fastest small-batch turnaround: 24-hour rapid delivery.

Advanced Technology:

PCBAgroup is equipped with a professional R&D team and ERP & MES production management system.

24/7 Service:

PCBAgroup engineers provide end-to-end support, ensuring worry-free quality.

Best Purchase Experience:

No MOQ.

Best Value for Money:

Quality meets your needs; price aligns with your expectations. PCBAgroup offers multiple reliable supply chains.

After-Sales Service

PCBAgroup guarantees a complete refund in the event of quality discrepancies, without any conditions.

How to Place an Order and Request a Quote

1.Send Your Quote

Upload your design files and requirements to receive a transparent and accurate quotation.

2. Request Sample

Want to verify quality first? Request a sample to see our craftsmanship and material standards up close.

3. Place Your Order

Confirm the quote and lead time online. Sign the order to officially queue your project for production.

4. Start Production

Our expert team utilizes advanced equipment to begin manufacturing, strictly adhering to your specifications.

5. Quality Inspection

Every batch undergoes multiple automated and manual inspections to ensure zero-defect delivery.

6. Shipping

Once products pass final inspection, we arrange secure shipment using optimal logistics per your request.