PCBA Quality Control

MES System

MES System Overview

Our MES system links every PCBA to its process history—materials, operators, machines, parameters, and inspection records—in real time. It reduces human error with digital work instructions, enforces routing and checkpoints, and delivers fast traceability for quality audits and corrective actions.

Advantages of MES System

Full Process Traceability

Track every board from material receiving to final shipment. Each PCBA is assigned a unique ID with complete visibility into process steps, operators, machines, parameters, and inspection records.

Real-Time Quality Control & Alerts

Capture production and test data live and trigger instant alerts when values drift out of spec. This enables faster containment, quicker root-cause analysis, and reduced scrap or rework.

Standardized Work Instructions & Error Proofing

Deliver digital work instructions by station and product revision, with routing control and mandatory checkpoints. This prevents missed steps, wrong parts, and incorrect program or fixture usage.

Audit-Ready Reporting & Faster Corrective Actions

Generate consistent reports for customer audits and internal reviews, linking defects to batches, lines, and time windows. This shortens CAPA cycles and strengthens continuous improvement.

PCBA Quality Contral Process

To ensure stable quality and high reliability for every PCBA order, we follow a strict 8-step quality control process from pre-production review to final inspection.

01-Process review

Assess and inspect the particularity of the PCBA manufacturing process in advance, guide the production, and improve the quality from the process technology.

02-IQC Incoming Quality Control

1.Check whether the resistance and capacitance values are correct 2.Check whether the pads on the components and the board are consistent 3.Confirm whether the incoming quantity is accurate 4.Check whether the components are abnormal

03-SPI Solder Paste Inspection

SPI can detect whether the solder paste is sufficient and uniform, which can effectively prevent production quality problems in advance caused by poor solder paste printing.

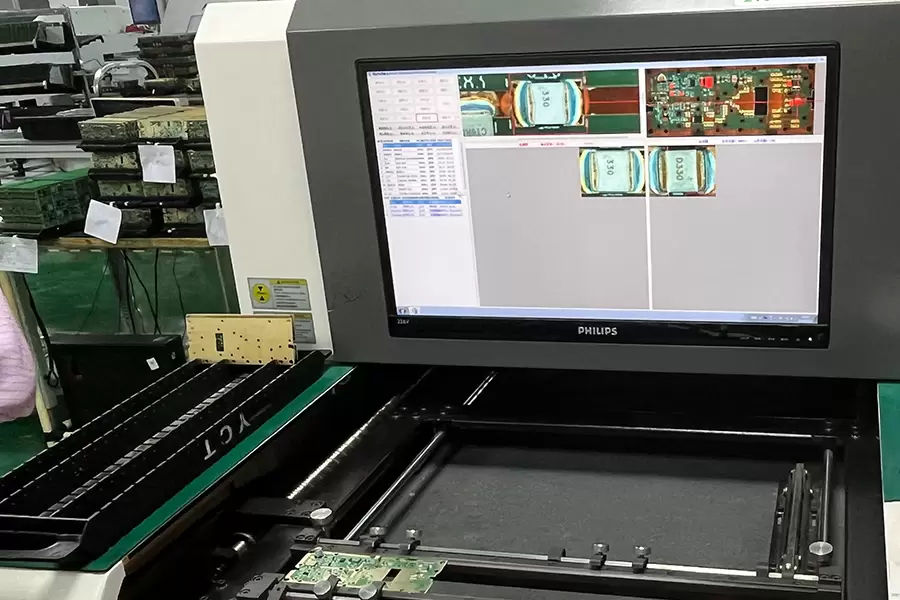

04-Online AOI Inspection

The AOI can detect the wrong solder, reverse solder, false solder, empty solder, incomplete solder, short circuit, offset, tombstone, etc. after reflow soldering. And it can also detect excessive solder, less solder, continuous solder and other undesirable phenomena in the appearance of PCBA solder joints.

05-First sample test

Combined with Gerber, BOM and coordinate files, the resistance and capacitance in the completed PCBA are verified again by the first-sample tester to ensure the correctness of all parameter values.

06-Off-line AOI inspection

According to the IPC610D standard, inspect the soldered surface mount PCBA for errors, omissions, and false connections.

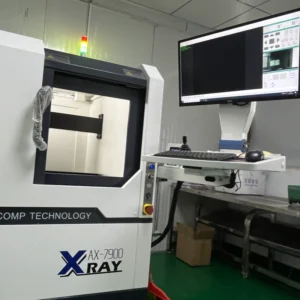

07-X-Ray welding inspection

Inspect the solder joints of invisible components to ensure the reliability of each solder ball of the BGA.

08-QC manual inspection

Refers to the standard IPC--610 inspection standard, and the finished board is visually inspected to ensure 100 % Good products shipped.

Environmental & Performance Testing Lab

Our Environmental & Performance Testing Lab helps validate assembly reliability before shipment and during NPI. With a constant temperature & humidity chamber, simulated transportation vibration testing, salt spray testing, battery testing, and BGA rework capability, we can support verification, troubleshooting, and corrective actions aligned with your product requirements.

Smart Advanced Equipment

How to Place an Order and Request a Quote

1.Send Your Quote

Upload your design files and requirements to receive a transparent and accurate quotation.

2. Request Sample

Want to verify quality first? Request a sample to see our craftsmanship and material standards up close.

3. Place Your Order

Confirm the quote and lead time online. Sign the order to officially queue your project for production.

4. Start Production

Our expert team utilizes advanced equipment to begin manufacturing, strictly adhering to your specifications.

5. Quality Inspection

Every batch undergoes multiple automated and manual inspections to ensure zero-defect delivery.

6. Shipping

Once products pass final inspection, we arrange secure shipment using optimal logistics per your request.